About Us

We are pleased to introduce ourselves as leading wear & tear engineers started in 1996 by a group of technocrats having collective experience of more than three decades then in maintenance and repair activities of core sector industry like cement, power, mining, sugar, paper, steel, infrastructure and oil drilling industry.

The X’tralife concept was introduced by the company with the motto of “Providing extra life to wear/tear prone components using the best available technology”

We have following business today to serve this purpose:

- Modular Products Business (MPB): Offers modular products like X’tralife composite wear plates, X’tralife NM wear plates, XL-AR Ceramics, X’trahard sintered composites, X’tralife burner tips, X’tralife screens, X’traslim wear plates, XL-Clad Tubes, X’tralife Rebuilding services at specialist workshop etc. MPB also offers ready to use wear resistant castings with or without hardfacing and critical spares for all core sector industry.

- Welding Products Business-1 (WPB-1): Offers welding products like X’tralife Low Thermal Welding Electrodes, X’tralife Tubular Electrodes, X’tralife Pastes, Fusible Powders, Underwater welding electrodes, Brazing alloys and lot of other products / techniques like X’tralife JIFFYTEMP INFRARED THERMOMETER (a non-contact temperature measurement device)

- Welding Products Business-2 (WPB-2): Offers welding wires/automation products like Solid & FCAW wire and Rebuilding with wires at site, WRTPLwelding machines and WRTPL welding automation equipment etc…

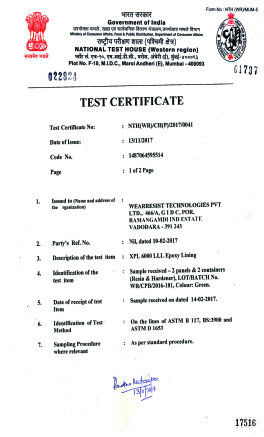

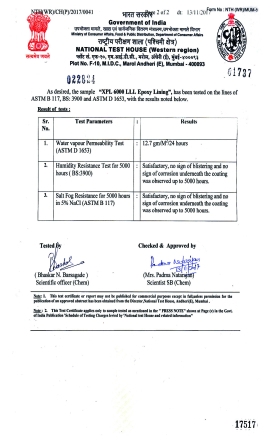

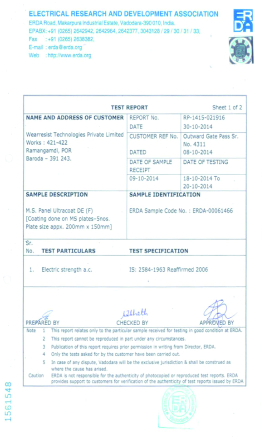

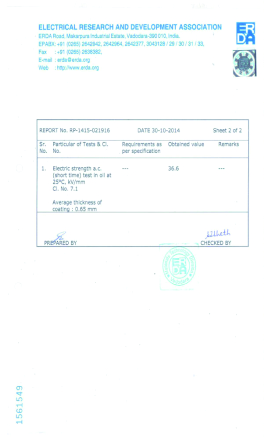

- Coating Products Business (CPB): Offers X’tralife bond coatings and R & M products, Floor Coatings, Industrial lining products which resist wear/corrosion from 0.5 to 14 pH chemicals. Also, it offers specialized Ultra Coatings like for fire Protection-insulation-improving flow properties etc as also WR-technical-sprays.

- Field Services Business: FSB executes welding, modular& Coating projects at site with own staff and specialized equipments.

- Ceramics and SVCC Coatings on Boilers and other high temperature erosion prone areas. Also, it executes metalizing and corrosion resistance projects at site. Additionally, it also does both internal / external specialized coating projects on metal and concrete surfaces.

- Ceramics and welding projects for repair and X’tralife treatment using stick electrodes.

- Ceramics and insitu rebuilding services on VRM roller / table liners as also roller press with 24×7 attitude using flux cored wires.

- Ceramics and specialized site welding services like repairs on kilns, repair of live rings, girth gears, hubs, supporting rollers, mill heads etc.

Markets

Markets Domestic Market: WRTPL is present all over India to

International Market: WRTPL has a fledged export division which exports X’tralife composite wear plates, maintenance welding Alloys, Flux cored Wires, industrial coatings etc. to GCC Countries, Africa, USA, China, Philippines, Indonesia, Malaysia, Bangladesh, Vietnam and venturing to other part of the Globe. WRTPL also provides in-situ services in these countries.

After Sales Service: WRTPL believes in strong after sales service through local geographical Sales teams. Also, welding technicians are posted locally for critical welding repairs and installation. Local Distributors stock a full range of WRTPL materials for timely material availability for unforeseen breakdowns.

Mission Statement

We, at WEARRESIST commit our selves to propagate the concept of XTRALIFE treatment through techno commercially economic solutions for both wear and repair problems in the core sector industry. Our endeavor would be to offer latest technology and treat customer as the boss and as our advertisement. Our resolve in Participating Management will bring out the best in our constituents.

“WEARRESIST” would keep on exploring new opportunities for “XTRALIFE” technologies thereby offering growth potential to its people, to the organization itself and to the society at large and offering value for money the customer spends.

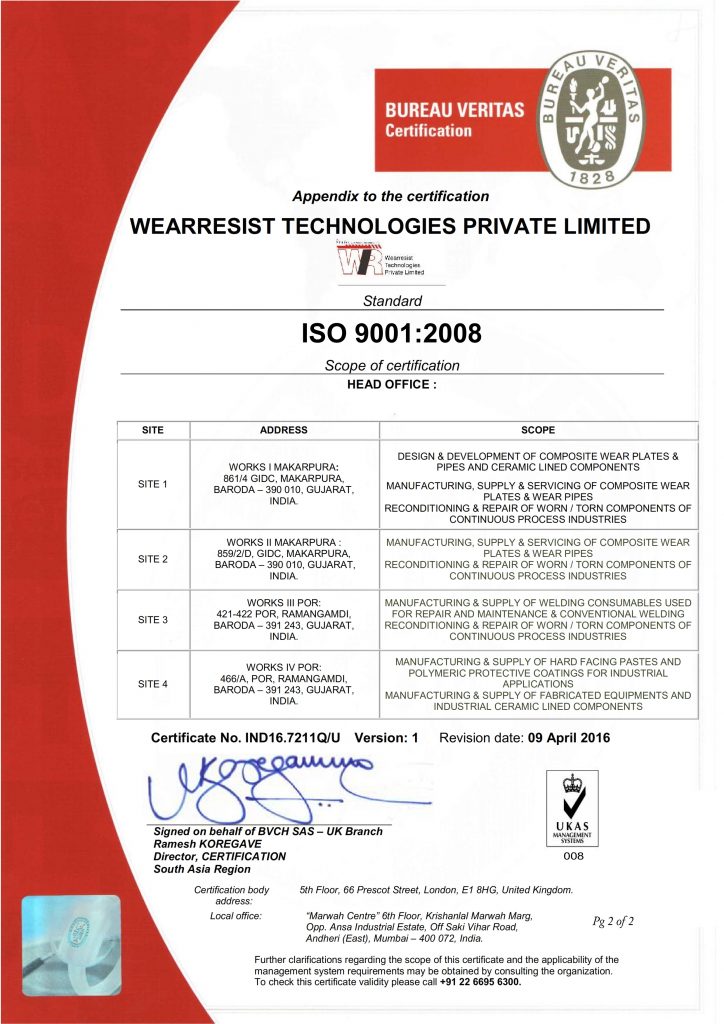

Quality Policy

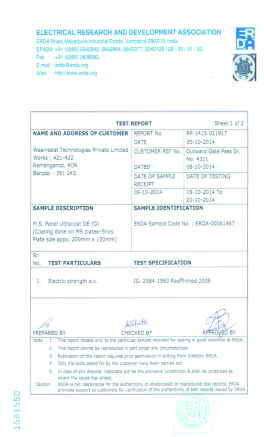

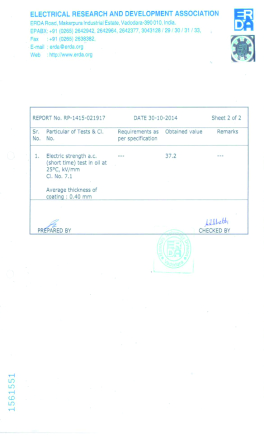

R & D and Custom Solutions

| WRTPL has an independent R&D wing. Since its inception, R&D activity has been given prime importance at WRTPL and R&D centre is attached to it’s Por Unit which is located in Vadodara Gujarat, India WRTPL’s research and development strategy is to continually improve its products and processes. The Company seeks to develop new, high quality product family faster, with the primary focus on long-term benefits, enhanced & consistent quality along with reduction of environmental impact. |